概要

Senior Chemical Engineer having 6+ years of experience in Chemical research, R&D Projects having ability to add innovative modifications in industrial processes. Having Added major contributions in financial growth of Company by reducing raw materials and Labor cost by 30% , helped to reduce utilities consumption and modified process arrangement to gain maximum productivity from available resources.

Major areas of expertise include Product development, Workforce Management, Innovative Process Modifications, Cost Optimization, Chemical Research, Lab Operations , and Water treatment Processes.

项目

工作经历

Chemical Engineer

Perform Research Work for the development of products that are cost-effective and have better quality.

To Develop and adjust the Chemical Formulation of the final Product(Safety Match) along with Managing the Cost of Raw materials & Utilities in Process.

Development of improved production flows and process Arrangements to increase productivity.

Maintain Good Manufacturing Practices within industrial Premises, making sure the health & safety of employees at the Plant.

Perform HSE Activities at the plant related to Chemical Hazards, Manage the HAZCOM program, Maintain Safety Data Sheets of Chemicals, installation of fire fighting tools and hoses/Sprays, and Provide PPEs to all employees as per their job.

Maintain a record of fire incidents, track their root cause, and develop solutions to eliminate and reduce causes to minimize machinery and production loss.

To Manage a team of thirty workers (Operators & labor), conduct training of workers related to work skills, and arrange their work to meet quality and production demands.

To develop procedures to reduce Process Waste, work cycle for waste reduction, & environment-friendly disposal procedures.

Perform R&D work for the Development of in-house Adhesives and Printing Inks & different variants of safety Match for export or local market.

Coordinate with CEO, and Production Manager related to quality issues, discuss market complaints, and develop solutions for product-related problems.

Perform Chemical Testing of stock chemicals, Maintain Laboratory Equipment, keep a record of quality tests, and develop procedures for testing of chemicals and final product.

Perform Troubleshooting of the Reverse Osmosis Plant & Cation Exchange Water Softening Plant to maintain Boiler water parameters as per limits and to prevent the boiler from internal corrosion & Scale.

Few Accomplishments Include:

Reduced Product Costs by 30% by substituting cost-effective alternate chemicals in formulation, and cut in production costs by reducing labor usage by one-third and utility usage (Steam, Water, Electricity, Machines Maintainance) by 20%.

Successfully developed export quality Safety Match formulation meeting European standard EN 1783 for export to European Countries.

By implementing HSE guides and plans, successfully reduced fire accident ratio by 90% and with almost zero fatalities or major injuries during work.

Successfully developed Flexo Printing Ink and Gravure Printing ink for company usage.

Reduced daily consumption of import chemicals by 30% by adjusting formulation, and addition of chemicals which helped to achieve the same quality with lower cost.

Maintain boiler internal and external treatment so that Coal-fired and Wood-fired boilers having a capacity of 6-ton steam/hr are running without any descaling performed since last 6 years or any corrosion issue detected.

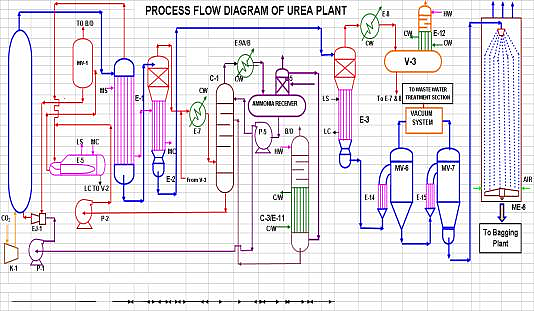

Internee Engineer

I have four weeks internship experience in production department of Sitara Chemical Industries (Pvt) Ltd. Faisalabad

学历

University of Engineering & Technology

Govt. Degree College Tandlianwala

技能

语言

推荐

Muhammad Shahid Butt

Noman is the kind of leader any company would be lucky to have. A true asset.