概要

An outgoing, dedicated and hardworking student of mechanical engineering with good communication and management skills presently, seeking a challenging position in a progressive organization. Who has an aim to contribute positively towards the achievement of its objectives to the best of his capabilities and to develop and improve his professional skills

项目

工作经历

Assistant Manager Production

1. Overseeing production processes Supervise and coordinate the production team to ensure efficient and high-quality production of upholstered furniture.

2. Quality control Implement and enforce quality standards, ensuring that products meet customer and company requirements.

3. Production planning Assist in planning and scheduling production to meet deadlines and optimize resource allocation.

4. Team management Lead, train, and develop a team of production staff, promoting a positive and productive work environment.

5. Material management Ensure adequate supply and management of materials, such as fabrics, foams, and frames.

6. Process improvement Identify areas for improvement and implement changes to increase efficiency, reduce waste, and enhance product quality.

7. Communication Collaborate with other departments, such as design, sales, and procurement, to ensure effective communication and coordination.

8. Problem-solving Troubleshoot production issues and implement solutions to minimize downtime and maintain productivity.

9. Cost control Assist in controlling production costs, optimizing resource usage, and minimizing waste.

10. Compliance Ensure adherence to safety regulations, industry standards, and company policies

Production Engineer

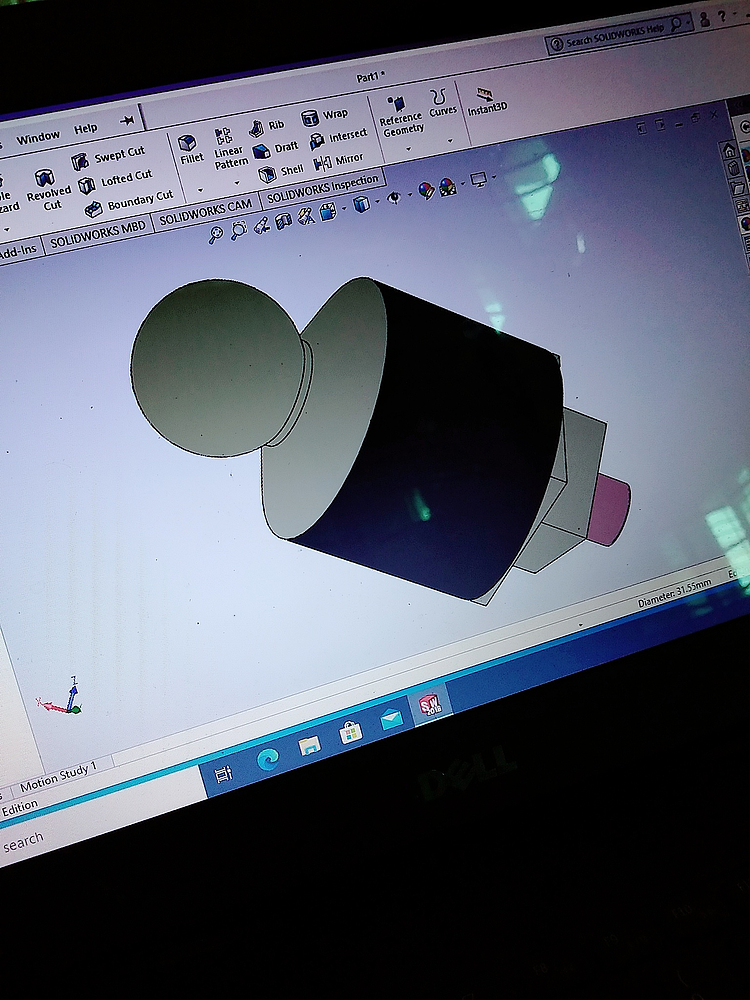

Experienced Production Executive with a demonstrated history of working in the furniture industry. Skilled in AutoCAD, SolidWorks, Inspection, Mathematics, and Maintenance & Repair. Strong operations professional with a Mechanical Engineering focused in Mechatronics, Robotics, and Automation Engineering from University of Engineering and Technology, Lahore.

Production & Maintenance engineer

· Maintenance of all production machines

· Supervising the whole Production line including production reports

· Keep Tracking production variations and reports

· Troubleshooting of all Mechanically and Electrically problems

Mechanical Engineer

· Worked on Lathe, Milling, Drilling Machines, Machining Centre, Turning Centre and Coordinate Measuring Machine.

· Learnt the software skills like SolidWorks, Master CAM.

· Observed the TIG welding process

manage the team to peform working on CNC Turning Center

Mechanical Engineer

· Prepared different parts of Bowser on Lathe Machine

· Observed the complete assembly of LPG cylinders

· Worked on Bowser assembly using Stick and Submerged Welding