خلاصہ

Dear Sir, I want to express my interest in joining your team. Please accept my CV in application for suitable position. My education and diversified jobs has prepared me well for the corporate world and I am submitting my CV for your review. When you review my CV, you will find that my background includes Mechanical Engineering, Quality Control and Assurance. In addition, you will find me a well-organized team member with excellent problem solving skills, my innovative approach to systems with my desire to learn, will prove to be an asset to my employer. My work Experience is as under: Presently working in “Automotive Manufacturing Organization” as “Sr. Executive Quality C/A” since Aug 2016. I am confident that my education and experience have prepared me for the position you have available and my unique abilities will enable me to contribute significantly towards your objectives. Thank you for your time, consideration and forthcoming response. . Kindly look into this. Thanking You, Best Regards, Muhammad Farhan Siddiq

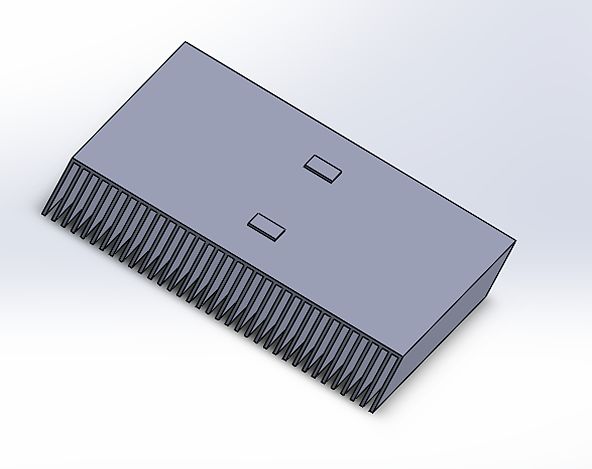

پراجیکٹس

تجربہ

Sr. Executive Quality C/A

· Prepare Presentations, Reports and Proposals for Parts Quality Improvement.

· Reduced quality complaint handling process time. Maintained and updated the product user guide. Ensures that products confer with respective quality standards and customer specifications at all manufacturing and quality inspection stages (incoming, in-process, final inspection).

· Performed HSE activities with compliance to Company HSE Policy.

· Trained Inspectors, Shop In-charges and welder in company inspection processes.

· Mediated transfer of Contract work for new products and redesign of work area for process flow.

· Maintained quality assurance per client standards for all weld joints and testing documentations, weld procedures and manufacturing instructions are developed, Implemented and maintained.

· Monitored and corrected weld related defects in all fabrication and assembly areas. Documented all welding activities and generated bi-weekly reports to management. Prepared and Publish quality documents, citing code and internal quality requirement.

· Consistently implemented Plans, which successfully reduce cycle time.

· Develop Quality related documents MOS, CAR, WIS, Pareto Analysis, Control & Run Chart, Quality Plan and Daily line Rejection/Repairing report. Implement cycle time improvement in Spot Welding.

· Identification of areas for improvement & critical significance to reduce Rejection & Rework.

· Quality Policy objective planning.

· Organizing and conducting quality awareness training for employees.

· Implementing and audit for ISO 9001:2015 QMS & Maintain the ISO Standards throughout the plant

· Conducted internal quality audit for various department to meet the requirements of ISO 9001:2015.

· Plan, implement and manage procedures to optimize inventory control as per QMS.

· Update inventory for Examine the levels of supplies and raw material to determine shortages, daily deliveries and shipments as per ISO 9001 Standards.

· Evaluate new inventory to ensure it’s ready for shipment & daily analysis to predict potential problems.

· Meeting with quality control, R&D and PPC team for improvement action plan & its effective execution.

· Maintaining proper documentation for inward, outward, issuance, Returnable and stock level in SAP.

· Analyze data to anticipate future needs & Place orders to replenish stock avoiding insufficiencies or excessive surplus.

· Coordination with OEM’s regarding their feedback related to minor or major defects of products.

· Immediate adjustments of production & inspection processes according to OEM’s feedback.

· Preparation of defect investigation report as per OEM’s requirements.

· Meeting with quality control, R&D and PPC team for improvement action plan & its effective execution.

· Follow up of improvement action plans for on time execution.

· Verification of results of improvements & execution of permanent adjustments or changes in process.