خلاصہ

Energetic Quality Assurance & Compliance professional with a demonstrated history of working with the multinational manufacturing facilities. Skilled in Quality Assurance/Control, Manufacturing Process, Lean Manufacturing, Quality Management System, Operational and Administrative Management, Health Safety, Consumer Behavior and Computer applications.

Enthusiastic professional with an Associate Engineering Diploma focused Mechanical Technology, Graduation focused in Administration and Commerce and Masters in Business Administration specialized in Supply Chain Management.

Seeking for a Management level position in Manufacturing, Production, Administrative and Logistics Industries.

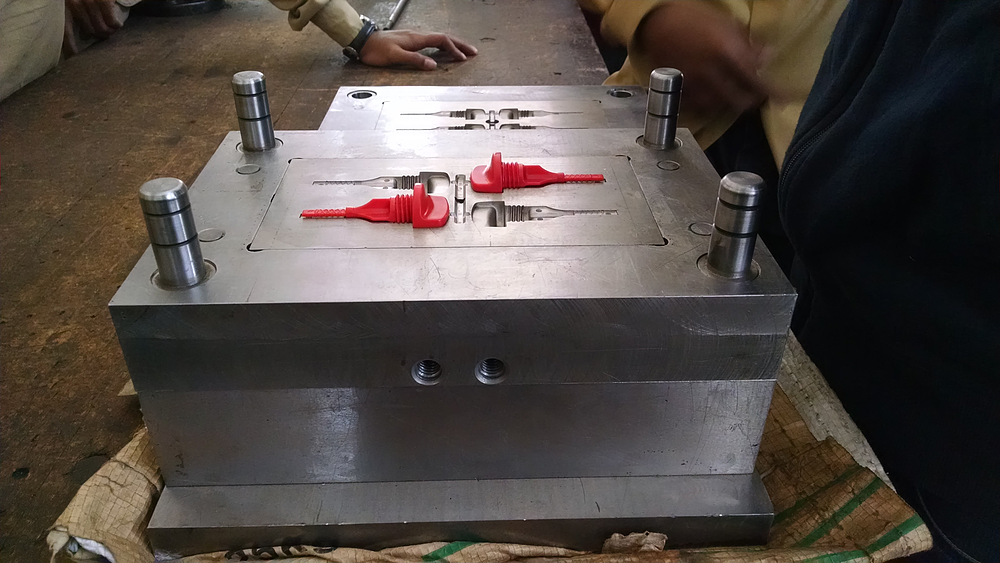

پراجیکٹس

تجربہ

Assistant Manager

Assisting department head in daily functions

Executive Quality Assurance

I provided my services in Yamaha Motor Pakistan, fulfilling following responsibilities. NEW MODEL EVALUATION AND ENDURANCE Planning for evaluation testing of new models and newly localized parts. Implementation of evaluation testing as per plan and information/results sharing with concern departments through meetings and presentations.MARKET CLAIM AND AFTER SALES Monitoring of market claim parts and trend of problematic parts reported after sales. Problem analysis of problematic parts and information sharing with concern manufacturing departments and vendors. Conduct routine and monthly meetings for information circulation of after sales condition of product and total retail sales vs market claim ratio. QUALITY MANAGEMENT SYSTEM (QMS) Preparation of SOPs and Rules as per Japan standard. Ensuring the implementation of SOPs and standards in all the departments. HSE MANAGEMENT (HEALTH AND SAFETY) Ensure health and safety of QA team and subordinates during evaluation testing and routine tasks. Also conduct monthly safety petrol to ensure the safety of other departments. Coordinate with Administration and procurement teams for HSE issues and purchasing of safety equipment. Ensure 5S of workplace and approach team towards KIZEN (Continuous improvement in process).

Quality Assurance Officer

I have provided my services in Auvitronics Ltd. as QA Officer (Grade II) for 2.5 years and successfully fulfilled the following responsibilities. Monitoring and Auditing of Product and manufacturing process to ensure high standards of quality. Analyze the root cause and prepare effective countermeasures in case of any error. Preparing all the documents for product development such as, Checking fixture concepts, Part inspection standards, Design review reports and Standard data sheets. Ensuring the implementation of SOPs and ISO standards in all the departments. Preparing quality feedback reports, SIS reports, defect review reports, standard data sheets and SOPs. Ensuring that all the quality assurance tests are carried out on time and according to the SOP. Maintaining the record of received products from vendors and all the in-house activities.